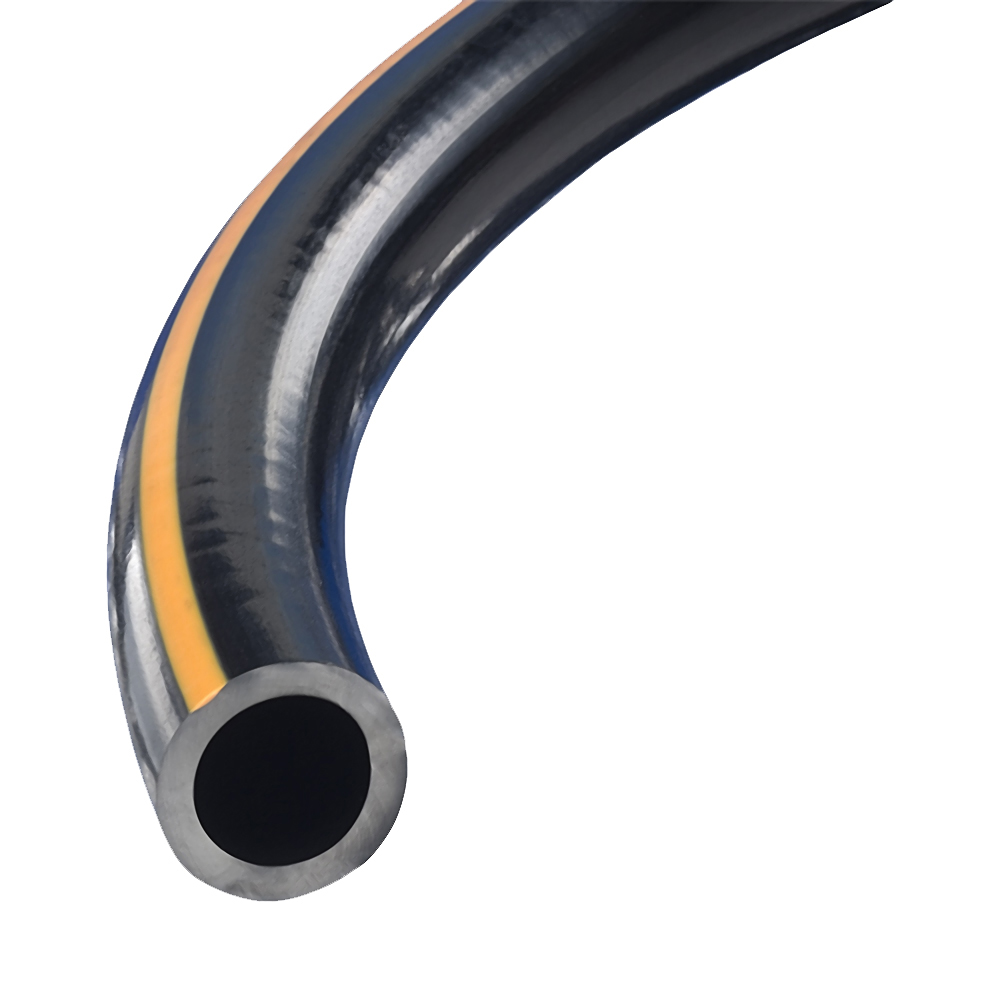

Tube:

Nitrile synthetic rubber, ARPM Class B (Medium Oil Resistance)

Cover:

Yellow Chemivic synthetic rubber, ARPM Class B (Medium Oil Resistance) (Meets flame test requirements of MSHA Schedule 26-Section 18.65), smooth finish

Reinforcement:

Braided (1) steel wire

Branding:

Example: Continental ContiTech Flexsteel® Mine Spray 1″ 1,000 psi WP Fire-resistant Made in USA

Temperature:

-20˚F to 210˚F (-29˚C to 99˚C)

Packaging:

3/4″ – 500′ reels or 50′ cut lengths, 20 pieces per carton

1″ – 500′ reels or 50′ cut lengths, 12 pieces per carton

1e” – 500′ reels or 50′ cut lengths, 8 pieces per carton

1f” – 300′ reels or 50′ cut lengths, 6 pieces per carton

2″ – 50′ cut lengths, 4 pieces per carton

Applications:

Flexsteel® Mine Spray is for general underground water spray service in dust control applications. It is also used on continuous mining machinery at the headface and on other mechanical mining machines.

| Item # | I.D. | Nom. O.D. | Max. WP | Weight |

|---|---|---|---|---|

| 20024121 | 3/4 in 19.1 mm | 1.14 in 29.0 mm | 1000 psi 6.9 MPa | 0.44 lb./ft. 0.65 kg/m |

| 20024129 | 1 in 25.4 mm | 1.45 in 36.8 mm | 1000 psi 6.9 MPa | 0.63 lb./ft. 0.94 kg/m |

| 20024138 | 1-1/4 in 31.8 mm | 1.75 in 44.5 mm | 1000 psi 6.9 MPa | 0.86 lb./ft. 1.28 kg/m |

| 20024143 | 1-1/2 in 38.1 mm | 1.98 in 50.3 mm | 1000 psi 6.9 MPa | 1.08 lb./ft. 1.61 kg/m |

| 20024154 | 2 in 50.8 mm | 2.55 in 64.8 mm | 1000 psi 6.9 MPa | 1.57 lb./ft. 2.34 kg/m |

Flextra® Rock Dust Mine Hose

Tube:

Black Chemituf® synthetic rubber (static dissipating/static conductive)

Cover:

Yellow Chemivic synthetic rubber, flame-resistant (MSHA) (wrapped impression)

Reinforcement:

Spiral-plied synthetic fabric with wire helix

Branding:

Example: Continental ContiTech Rock Dust Flame-resistant MSHA IC 11/7

Temperature:

-25˚F to 200˚F (-32˚C to 93˚C)

Packaging:

50′ lengths, coiled and poly-wrapped

Applications:

For handling rock dust operations in underground mines.

| Item # | I.D. | Nom. O.D. | Max. WP | Bend Radius | Vacuum HG | Weight |

|---|---|---|---|---|---|---|

| 20020003 | 1-1/4 in 31.8 mm | 1.59 in 40.5 mm | 100 psi 0.69 MPa | 6 in 152 mm | 29 in 737 mm | 0.48 lb./ft 0.72 kg/m |

| 20020005 | 1-1/2 in 38.1 mm | 1.85 in 46.9 mm | 100 psi 0.69 MPa | 6 in 152 mm | 29 in 737 mm | 0.60 lb./ft. 0.89 kg/m |

| 20020009 | 2 in 50.8 mm | 2.37 in 60.3 mm | 100 psi 0.69 MPa | 8 in 203 mm | 29 in 737 mm | 0.80 lb./ft. 1.19 kg/m |

| 20020011 | 2-1/2 in 63.5 mm | 2.89 in 73.3 mm | 100 psi 0.69 MPa | 10 in 254 mm | 29 in 737 mm | 1.06 lb./ft. 1.58 kg/m |

| 20020012 | 3 in 76.2 mm | 3.35 in 85.1 mm | 50 psi 0.34 MPa | 12 in 305 mm | 29 in 737 mm | 1.20 lb./ft. 1.79 kg/m |

| 20020013 | 4 in 101.6 mm | 4.41 in 111.9 mm | 50 psi 0.34 MPa | 16 in 406 mm | 29 in 737 mm | 1.71 lb./ft. 2.55 kg/m |

M&P Mine Conduit

Tube:

Black flame-resistant synthetic

Cover:

Black flame-resistant synthetic (smooth cover)

Reinforcement:

Spiral synthetic yarn

Branding:

Example: 3/4″ (19.1 mm) Mine Conduit Made in USA Continental ContiTech US MSHA #2G-14-7X

Temperature:

-20˚F to 200˚F (-29˚C to 93˚C)

Packaging:

Stocked in 50′ pieces per box

Applications:

A fabric-reinforced conduit hose for use as an electrical cable cover in underground mine service.

| Item # | I.D. | Nom. O.D. | Weight |

|---|---|---|---|

| 20026402 | 1/2 in 12.7 mm | 0.94 in 23.9 mm | 0.29 lb./ft. 0.43 kg/m |

| 20026405 | 5/8 in 15.9 mm | 1.06 in 26.9 mm | 0.35 lb./ft. 0.52 kg/m |

| 20026409 | 3/4 in 19.1 mm | 1.19 in 30.2 mm | 0.39 lb./ft. 0.58 kg/m |

| 20026412 | 7/8 in 22.2 mm | 1.32 in 33.5 mm | 0.45 lb./ft. 0.67 kg/m |

| 20026415 | 1 in 25.4 mm | 1.43 in 36.3 mm | 0.46 lb./ft. 0.68 kg/m |

| 20026417 | 1-1/8 in 28.6 mm | 1.56 in 39.6 mm | 0.60 lb./ft. 0.89 kg/m |

| 20026419 | 1-1/4 in 31.8 mm | 1.69 in 42.9 mm | 0.62 lb./ft. 0.92 kg/m |

| 20026421 | 1-3/8 in 34.9 mm | 1.82 in 46.2 mm | 0.71 lb./ft. 1.06 kg/m |

| 20026423 | 1-1/2 in 38.1 mm | 1.95 in 49.5 mm | 0.75 lb./ft. 1.12 kg/m |

Plicord® Mine Conduit

Tube:

Black Wingprene® synthetic rubber

Cover:

Black Wingprene® synthetic rubber, flame-resistant (wrapped impression)

Reinforcement:

Spiral-plied synthetic fabric

Branding:

Example: Continental ContiTech Mine Conduit Hose

Flame-resistant USMSHA #2G-14/15

Temperature:

-40˚F to 200˚F (-40˚C to 93˚C)

Packaging:

50′ lengths, coiled and poly-wrapped

Applications:

Plicord® Mine Conduit is a fabric-reinforced hose for use as an electrical cable cover in underground mines. This hose meets MSHA standards for flame-resistant cover.

| Item # | I.D. | Nom. O.D. | Weight | |

|---|---|---|---|---|

| BLACK | YELLOW | |||

| 20019080 | 20019068 | 1/2 in 12.7 mm | 0.94 in 23.9 mm | 0.30 lb./ft. 0.45 kg/m |

| 20019082 | 20019070 | 5/8 in 15.9 mm | 1.06 in 26.9 mm | 0.35 lb./ft. 0.52 kg/m |

| 20019084 | 20019071 | 3/4 in 19.1 mm | 1.18 in 30.0 mm | 0.40 lb./ft. 0.60 kg/m |

| 20019087 | 20019072 | 7/8 in 22.2 mm | 1.30 in 33.0 mm | 0.45 lb./ft. 0.67 kg/m |

| 20019089 | 20019073 | 1 in 25.4 mm | 1.43 in 36.3 mm | 0.50 lb./ft. 0.74 kg/m |

| 20019091 | 20019075 | 1-1/8 in 28.6 mm | 1.58 in 40.1 mm | 0.56 lb./ft. 0.83 kg/m |

| 20019093 | 20045963 | 1-1/4 in 31.8 mm | 1.69 in 42.9 mm | 0.61 lb./ft. 0.91 kg/m |

| 20019095 | 20031917 | 1-3/8 in 34.9 mm | 1.81 in 46.0 mm | 0.66 lb./ft. 0.98 kg/m |

| 20019096 | 20029879 | 1-1/2 in 38.1 mm | 1.93 in 49.0 mm | 0.71 lb./ft. 1.06 kg/m |

| 20019099 | 20031918 | 1-3/4 in 44.5 mm | 2.21 in 56.1 mm | 0.82 lb./ft. 1.22 kg/m |

| 20019102 | 20019076 | 2 in 50.8 mm | 2.42 in 61.5 mm | 0.87 lb./ft. 1.29 kg/m |

| 20019107 | 2-1/4 in 57.2 mm | 2.67 in 67.9 mm | 0.97 lb./ft. 1.43 kg/m |

|

| 20019108 | 2-3/8 in 60.3 mm | 2.80 in 71.0 mm | 1.02 lb./ft. 1.52 kg/m |

|

| 20019109 | 20029631 | 2-1/2 in 63.5 mm | 2.92 in 74.2 mm | 1.06 lb./ft. 1.58 kg/m |

| 20019112 | 3 in 76.2 mm | 3.41 in 86.5 mm | 1.26 lb./ft. 1.86 kg/m |

|

| 20019115 | 4 in 101.6 mm | 4.44 in 112.7 mm | 1.66 lb./ft. 2.45 kg/m |

Plicord® Ammonium Nitrate HD Mine Hose

Tube:

Black nitrile synthetic rubber (static dissipating/static conductive)

Cover:

Black nitrile synthetic rubber (static dissipating/static conductive) (wrapped impression)

Reinforcement:

Spiral-plied synthetic fabric recommendation and coupling procedure

Branding:

Continuous spiral brand “HD Ammonium Nitrate Pellet 400 psi Max WP Continental ContiTech Made in Canada”

Temperature:

-25˚F to 200˚F (-32˚C to 93˚C)

Packaging:

Coiled and poly-wrapped

Applications:

This hose is a heavy-duty hose for pellet transfer in blasting hole loading. Capable of handling -25˚F to 200˚F (-32˚C to 93˚C).

| Item # | I.D. | Nom. O.D. | Max. WP | Weight |

|---|---|---|---|---|

| 20019412 | 1 in 25.4 mm | 1.60 in 40.6 mm | 400 psi 2.76 MPa | 0.63 lb./ft. 0.94 kg/m |

| 20019413 | 1-1/2 in 38.1 mm | 2.10 in 53.3 mm | 400 psi 2.76 MPa | 0.87 lb./ft. 1.30 kg/m |

| 20115495 | 1-3/4 in 45.1 mm | 2.61 in 66.3 mm | 400 psi 2.76 MPa | 1.49 lb./ft. 2.21 kg/m |

| 20118678 | 2 in 50.8 mm | 2.84 in 72.0 mm | 400 psi 2.76 MPa | 1.64 lb./ft. 2.44 kg/m |

| 20135894 | 2-1/2 in 63.5 mm | 3.26 in 82.7 mm | 400 psi 2.76 MPa | 1.76 lb./ft. 2.62 kg/m |

| 20368039 | 3 in 76.2 mm | 3.71 in 94.2 mm | 400 psi 2.76 MPa | 1.92 lb./ft. 2.86 kg/m |

Spiraflex® Cable Guard

Tube:

Clear Pliovic® corrugated for flexibility, MSHA

Helix:

Clear Pliovic® corrugated for flexibility, MSHA

Branding:

Example: Cable Guard USMSHA IC-11/12 Made in USA Continental ContiTech

Temperature:

0˚F to 150˚F (-18˚C to 66˚C)

Packaging:

Continuous one-piece, coiled and poly-wrapped, available in 50′ or 100′ lengths. Available pre-slit longitudinally for easy installation

Applications:

This hose is for use as a protective cover for supply lines. It is flame-resistant and MSHA-approved.

| Item # | I.D. | Nom. O.D. | Bend Radius | Weight |

|---|---|---|---|---|

| 20013419 | 2 in 50.8 mm | 2.28 in 57.9 mm | 3 in 76 mm | 0.34 lb./ft. 0.51 kg/m |

| 20013425 | 3 in 76.2 mm | 3.37 in 85.6 mm | 6 in 152 mm | 0.52 lb./ft. 0.77 kg/m |

| 20013431 | 4 in 101.6 mm | 4.44 in 112.8 mm | 9 in 229 mm | 0.75 lb./ft. 1.12 kg/m |

Series No. K7000-12X200, Series K7000 Anti-Stat Blasting Tubing

Applications:

- Bulk unloading of ammonium nitrate/fuel oil blasting agents in small diameter holes.

- Successfully used for years with Orica’s blast hole chargers, intermediate loaders and the Penberthy Anoloader.

- Mining and construction site blasting.

| Item # | I.D. | Nom. O.D. | Max WP | Weight | Length/Coil |

|---|---|---|---|---|---|

| K7000 | 3/4 in 19 mm | 1 1/16 in 27 mm | 120 psi 0.8 MPa | 28 lb | 200 ft 61 m |

Kuri Tec – K-Tough – K9296 Series High Pressure Wire & Yarn Reinforced Suction & Discharge Hose

| Item # | Nom. I.D. | Nom. O.D. | Max. Working Pressure at 70 ºF (20 ºC) | Vacuum Rating at 70ºF (20ºC) | Length | Weight /package | Min. Bend Radius at 70ºF (20ºC) |

|---|---|---|---|---|---|---|---|

| K9296-24X50 | 1.50 in 38.1 mm | 2.03 in 51.6 mm | 300 psi | 29.9 inHg | 50 ft | 45 lb | 5.5 in |

| K9296-24X100 | 1.50 in 38.1 mm | 2.03 in 51.6 mm | 300 psi | 29.9 inHg | 100 ft | 90 lb | 5.5 in |

| K9296-32X50 | 2.00 in 50.8 mm | 2.57 in 65.3 mm | 275 psi | 29.9 inHg | 50 ft | 62 lb | 7.0 in |

| K9296-32X100 | 2.00 in 50.8 mm | 2.57 in 65.3 mm | 275 psi | 29.9 inHg | 100 ft | 124 lb | 7.0 in |

| K9296-40X50 | 2.50 in 63.5 mm | 3.07 in 78.0 mm | 150 psi | 29.9 inHg | 50 ft | 79 lb | 9.0 in |

| K9296-40X100 | 2.50 in 63.5 mm | 3.07 in 78.0 mm | 150 psi | 29.9 inHg | 100 ft | 158 lb | 9.0 in |

| K9296-48X50 | 3.00 in 76.2 mm | 3.57 in 90.7 mm | 150 psi | 29.9 inHg | 50 ft | 90 lb | 11.0 in |

| K9296-48X100 | 3.00 in 76.2 mm | 3.57 in 90.7 mm | 150 psi | 29.9 inHg | 100 ft | 180 lb | 11.0 in |